Cushioned Propeller Guard – Senior Design Project

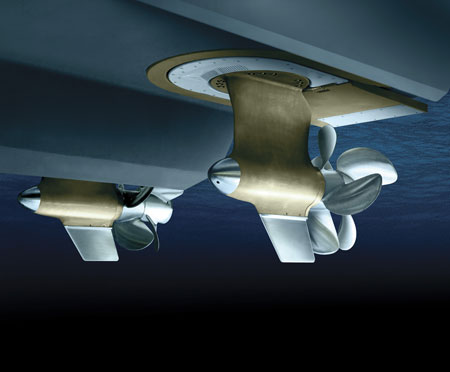

Marine drive companies have long employed damping / cushioning technologies to protect marine drives, most typically trim cylinder log strike systems that allow the drive to swing back, up, and over underwater obstacles. Recent years have brought several through hull drives to the market, most prominently Volvo Penta’s IPS, and Brunswick’s / Cummins Mercruiser Diesel (CMD) Zeus Pod Drive.

These thru hull drives, typically used on larger boats, are no longer able to be protected by the trim cylinder log strike systems because the drives do not trim. Volvo Penta and Mercury Marine / Brunswick have been issued several patents for break away drives and other techniques to protect the drive and especially to prevent the boat from sinking if the drive strikes a major obstacle, like a large rock.In November 2011, Brunswick was issued U.S. Patent 8,062,082 for a “Marine Drive With Staged Energy Absorption Capability”. Targeting through hull drives, the patent describes a drive with a long, crushable nose cone. Depending on the amount of energy to be expended when a drive strikes an obstacle (speed of boat and mass of the boat), the nose cone can crush to absorb the energy, or the drive can “breakaway” from the boat. At lower energies (lighter boats and slower speeds) the nose cone crushes to absorb the energy, slow the boat, protect the main part of the drive, and prevent the boat from stopping so fast that people would be ejected. At higher energies (heavier boats and faster speeds), the drive breaks away in a manner that maintains the integrity of the hull and prevents water from entering the boat. The patent includes several charts showing the deceleration capabilities of varies designs. Brunswick introduces the idea of not only crushing the nosecone to absorb the energy, but also of allowing water to fill the nosecone, then forcing it out through one or more orifices during a collision, of filling the cone with an impact absorbing structure, filling the nosecone with an energy absorbing foam, and review previous approaches by others.

The industry is identifying technologies that can protect the boat, and the drive, and do so in a way that does not cause sufficient rapid deceleration to eject people from the boat.

Some of the earlier technologies, and the some of the more recent developments appear to hold significant promise for being able to reduce the impact / blunt trauma felt by humans when struck by a propeller guard. Anything that can reduce the rapid acceleration felt by humans when struck by a marine drive or guard AND the duration of that acceleration is a candidate for reducing injuries and their severity.

We anticipate publishing a post on the science behind blunt trauma injuries in the future which should also be a helpful reference to those pursuing this project. For those not familiar with blunt trauma injuries or who just think of them resulting from being whacked or hit with something, blunt trauma injuries result from sudden accelerations or sudden decelerations. Our organs, tissues, and even bones are damaged when they are accelerated or decelerated too quickly. Blunt trauma injuries can be reduced by reducing the peak accelerations and decelerations of humans struck by propeller guards.

We propose students consider Cushioned Propeller Guard design projects for their Senior Design Projects, Sr. Thesis, and Capstone projects to better protect humans and marine life from being struck by a propeller guard, and provide further information below.

The Old Way – Trim Cylinder Log Strike Systems

For decades, drives and boats have been protected by log strike systems built into trim cylinders. A combination of a trim cylinder piston with several relief valves built into the piston itself, a memory piston, and some check valves also in the piston head allow the cylinder rod to extend when striking underwater obstacles. The drive swings back up and over the obstacle, then gravity pulls it back down, fluid flows back through the check valves, the cylinder piston comes back down to rest against the memory piston, and the drive is returned to its previous trim position.

Trim cylinder log strike systems are not practical for providing cushioning to humans because they are normally designed to crack at very high pressures. The impact / blunt trauma would could still be very severe or the system might never even open.

Trim Cylinder Trailout Proposed For Slower Stops

Back in the 1970’s Mercury Marine patented a two methods to allow the trim cylinders to “trail out” slowly at less than the high pressures required to crack the log strike system relief valves in the pistons. It was an attempt to prevent people from being ejected when a boat hit an underwater obstacle at slower speeds and might otherwise be brought to an abrupt halt because it was not going fast enough to build up the pressures require to open the relief valves. On page Page 135 of our analysis of USCG’s rejection of the houseboat propeller safety proposal we point out how those approaches might be used to reduce blunt trauma.

On that same page, page 135, we also identify a more recent Teleflex patent that appears could accomplish the same task, while actually being a cost reduction over current methods.

Both methods, the old Brunswick patents, and the more recent Teleflex patent look like candidates for reducing blunt trauma injuries to those struck by marine drives and / or propeller guards.

Use of Resilient Mounts

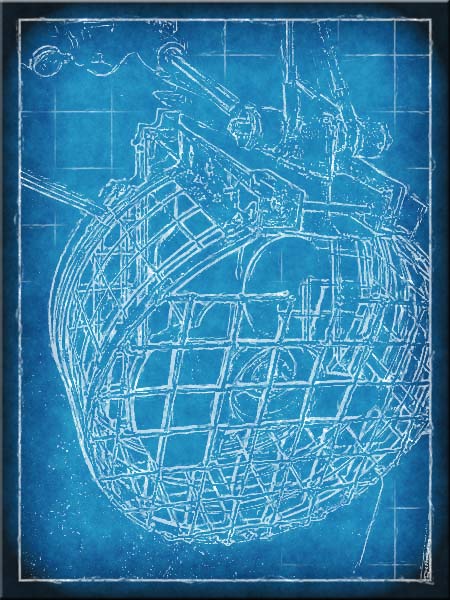

In our Shock Mounted, Forward Facing, Catchers Mask Propeller Guard Invention post we talk about the use of resilient, shock absorbing mounts as a potential means of reducing blunt trauma injuries resulting from being struck by a propeller guard.

Use of Springs

In February 2008, Enviroprop was issued two design patents for propeller guard bumper guard rails. U.S. Design Patents D562,209 and D562,210 show the use of springs we assume are are to cushion impacts. While design patents illustrate the appearance of the invention, they are unable to elaborate on its purpose or function. Enviroprop’s mounting methods may inspire other cushioning approaches.

Use of Special Materials

Deformable materials, shape memory materials, resilient materials, cushioning materials and other materials with special properties might lend themselves to use in a cushioned propeller guard.

Optimizing Guard Shape to Reduce Blunt Trauma

At least partially alluded to in our Shock Mounted, Forward Facing, Catchers Mask Propeller Guard invention post, designing a guard to minimize flat forward facing areas, and to provide gentle, directing slopes that brush people aside or roll them off the guard vs. smack them can also reduce blunt trauma.

We and others have previously put forth the concept of fiber guards (mesh braided from kevlar or similar fabrics). Properly designed fabric / fiber guards might reduce blunt trauma due to their stretchiness. Back in 2004, Aukland University Department of Engineering (New Zealand) and Stainless Design Limited of Hamilton, New Zealand worked on a Kevlar reinforced propeller guard for standard outboard motors. They called it the Aqua Guard.

“Plastic” propeller guards might compress on impact enough to reduce blunt trauma injuries.

Cushion People With Fluid Flow

It is certainly possible to redirect some flow to attempt to make some sort of flow barrier or people redirector. The problem is in doing so while not impacting the performance of the boat or any boat handling characteristics. In the past some have tried this with deflectors in front of the propeller that were intended to serve as a guard themselves (manatee bumpers, whale bumpers, Lyfguard Deflector, etc.) and claimed that not only were those devices physical barriers, but that they somehow redirected flows that prevented people from even striking their barriers.

Basic Structure of the Guard

Mesh type guards are thought to have more “spring” in them than guards composed of larger steel rods or ring type guards. The possible springiness of mesh type guards may reduce blunt trauma as compared to guards constructed of larger steel rods and plates.

Combination of Approaches

We suspect the best approach might involve using a combination of approaches to reduce blunt trauma injuries.

Some Potential Instrumentation

Recent years have seen many low cost, easy to use accelerometers enter the market. We noticed Stanford football players have been playing with instrumented mouthpieces from X2Impact, known as X2 Biosystems in 2013. By placing 3 axis accelerometers in mouthpieces, football impacts can be watched in real time. The work done by X2Impact might lend itself to the biomechanical testing of propeller guards. We recognize being underwater could create many issues for their existing instrumentation, but some of their methods might be utilized.

Since we first wrote this piece, X2 Biosystems has also developed tape on patches that go behind the ear as an alternative to mouthpieces.

Project

We encourage engineering and design students seeking topics for their Class Project, Senior Design Projects, Sr. Thesis, and Capstone Projects to consider designing and testing a cushioned propeller guard to reduce blunt trauma injuries. We suggest a few possible methods above, but are well aware fresh looks from students can generate other approaches that may be far more successful as well.

While most of our comments focused on traditional catchers mask looking propeller guards, a similar need exists for Ring or Octagonal propeller guards where the leading “edge” of the ring or octagon can cut people or produce blunt trauma injuries as well.If anyone is interested in pursuing a project like this, please contact us.